VCU oil and gas incineration device

Composition and main features of the vapor combustion unit (VCU)

VCU (Vapor Combustion Unit) is a novel system for treating oil and gas as well as VOCs waste gases. It is designed for most working conditions where oil and gas condensation recovery emissions fail to meet standards. Compared to RTO regenerative thermal oxidizers, VCU is more suitable for scenarios with high oil and gas concentrations, significant fluctuations, and unstable waste gas volumes. It features rapid start-up, a small footprint, and safety against backfires.

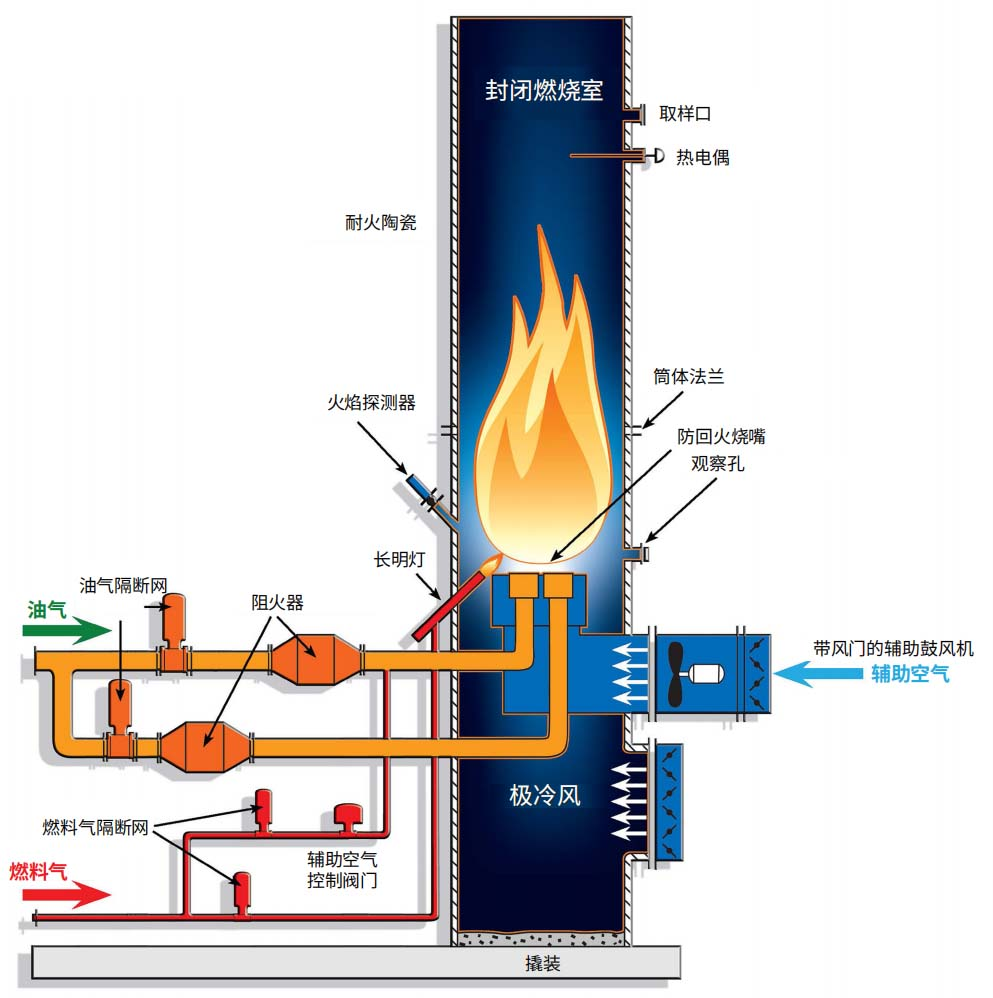

VCU primarily consists of a backfire-proof burner, pilot burner, combustion air fan, air regulating damper, combustion chamber, flame detector, fuel gas pipeline and associated control valves, oil and gas exhaust pipeline, booster fan, flame arrester, and ignition control system (see the figure below).

As the premier brand in the global combustion sector and the inventor of the VCU system, JOHNZINK boasts thousands of applications worldwide, backed by decades of experience in oil and gas control. We have engaged in in-depth technical collaboration with JOHNZINK, tailoring our development to the specific needs of Chinese customers, particularly focusing on the system design and development of VCU oil and gas combustion devices for oil storage and transportation in tank areas, as well as oil and gas collection and treatment in loading and unloading areas. This product is fully deserving of your trust. The device features the following advantages:

safe and stable

The flame arrester provides the primary backfire protection. Based on our proprietary burner and operating procedures, the device does not require liquid sealing.

+ The anti-backfire burner can safely burn explosive mixtures that standard burners cannot handle. The burner manufactured by JOHNZINK factory can effectively prevent backfire and provide stable combustion within a relatively wide range of flow rates and concentrations.

+ Special pilot lights, which are energy-saving and efficient, can provide a stable and continuous ignition source for oil and gas. Additionally, anti-backfire pilot lights suitable for high hydrogen fuel gas in refineries have been developed.

The burner staging logic ensures a sufficiently wide design load adjustment ratio, ensuring stable and safe combustion even at low flow rates.

The enclosed combustion chamber can completely conceal the flame and burn hydrocarbon gases and oils in a controllable manner. The combustion chamber is equipped with temperature detection, ultraviolet and infrared integrated flame detection, combustion-supporting fans, and other monitoring and temperature control measures.

High Efficiency and Energy Saving

+ Staged combustion and multiple combustion air fans can reduce the amount of fuel gas required for higher operational flexibility requirements.

+ The furnace temperature control of the oil and gas combustion device reduces the generation of nitrogen oxides.

The oil-gas equalizer used for gasoline or distillate gas can balance the oil and gas, collecting gasoline when the gas is rich and increasing oil and gas when the gas is lean. By equalizing the concentration of oil and gas, it can reduce or completely eliminate the need for auxiliary fuel.

+ A separate combustion-supporting burner can reduce the fuel consumption required for inert oil and gas, especially when the oil and gas are of low calorific value.

By premixing fuel with high-oxygen lean oil gas, the usage of fuel gas can be reduced.

The stable burner design meets emission requirements at lower operating temperatures, reducing fuel consumption.

+ Temperature control reduces fuel consumption, thereby achieving a higher removal rate.

Flexible modularization

+ Skid-mounted components reduce on-site installation time and costs. The enclosed cylinder bottom can also be skid-mounted and connected via flanges, saving you significant time and costs.

In cases of insufficient oil and gas pressure, we can provide complete sets of oil and gas fan equipment. A single integrated system is employed for the transmission and combustion of oil and gas.

+ In cases where the oil and gas contain high sulfur content or have recovery value, functional modules such as desulfurization modules and condensation recovery modules can be added to the system to meet emission requirements and economic indicators.

Uploading ..

Scope of application of the Vapor Combustion Unit (VCU)

+ Loading of trucks and railcars

+ Oil storage tank delivery and exhaust

+ Cargo ship and tank degassing

+ Loading of cargo ships and steamships

+ Reactors, dryers, and other process exhaust systems

+ Pipeline unloading station

+ Gas treatment of sewage pool

+ Separator and other wastewater discharge

Comparison between VCU incineration technology and traditional VOCs incineration RTO/CO technology

| workmanship | VCU combustion | TO (Direct Combustion Method) | RTO (Regenerative Thermal Oxidizer)) | CO (Catalytic Combustion Method) |

| processing efficiency | 99.9% | 98%-99% | 97%-98% | 97%-98% |

| safety | The core component utilizes a backfire-proof burner designed and manufactured by JOHNZINK, ensuring multiple physical safeguards for safe production throughout the entire process, providing stability and reliability. | Combustible fuel gas cannot directly enter the explosion range and requires pre-treatment at the front end. | Combustible fuel gas cannot directly enter the explosion range and requires pre-treatment at the front end. | Combustible fuel gas cannot directly enter the explosion range and requires pre-treatment at the front end. |

| Startup time | 8min | 1—2h | 2—4h | 1—2h |

| operational costs | low | high | middle | middle |

简体中文

简体中文