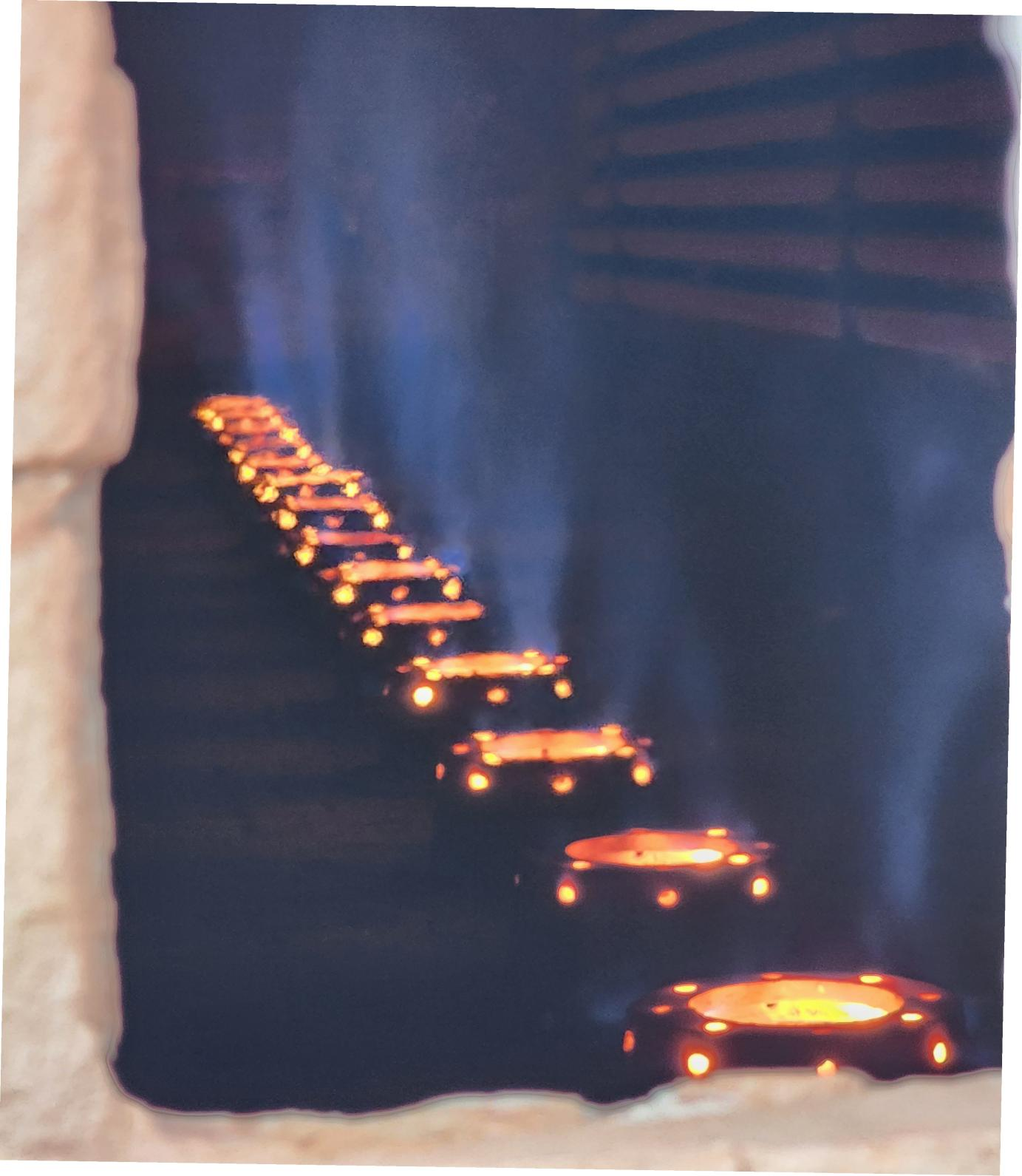

Process heater burner

Burner: Ultra-low nitrogen burners are a part of heating furnaces in the petrochemical and oil refining industries. Xianghongsheng engineers have summarized valuable experience and data, and designed process burners that integrate safety, ease of operation, and ultra-low emission performance from the perspective of customers. We provide low nitrogen burner solutions to customers worldwide, helping petrochemical companies improve energy efficiency and reduce emissions. Design Features: The excellent performance of the burner is attributed to the application of unique in-furnace flue gas recirculation technology, staged combustion technology, and technology that utilizes the intake kinetic energy of fuel gas and air to achieve air-fuel mixing. This breakthrough design stabilizes the flame, enhances fuel utilization, and reduces nitrogen oxide emissions.

Characteristics:

The adjustment ratio is high

10:1 NOx emissions are as low as single digits

It can replace the need for SCR or other nitrogen oxide reduction technologies

It exhibits stability under various fuel gas components and different combustion-supporting air temperatures

The air damper can be adjusted in multiple positions via a spring lock

Compact structure, suitable for retrofit projects, and applicable to traditional low-nitrogen burner opening sizes

The flame length is optimized and designed according to the internal conditions of the furnace chamber, matching the optimal heat exchange area of the furnace tube

Adopting a modular component assembly structure, it is easy to maintain and repair with low cost, featuring some easily detachable spray head modules.

The installation methods are diverse, allowing for bottom firing, top firing, and side firing

Technical Characteristics

We have designed and developed a unique structural design of refractory bricks for anti-backfire pilot lights suitable for fuels containing high hydrogen content, ensuring stable flame performance

Guidance and installation service

Upon arrival at the site, the goods will be counted and inspected. Spare parts will be sorted according to the models of furnaces and burners to facilitate installation. After installation, a comprehensive inspection of each burner, including refractory bricks, will be conducted to ensure that the nozzle orientation of each installed burner is correct and unblocked. After the start-up, the flame shape will be observed, and adjustments such as damper air distribution will be made for commissioning. The service will be completed after the heating furnace is running and the NOx emissions are qualified.

![]()

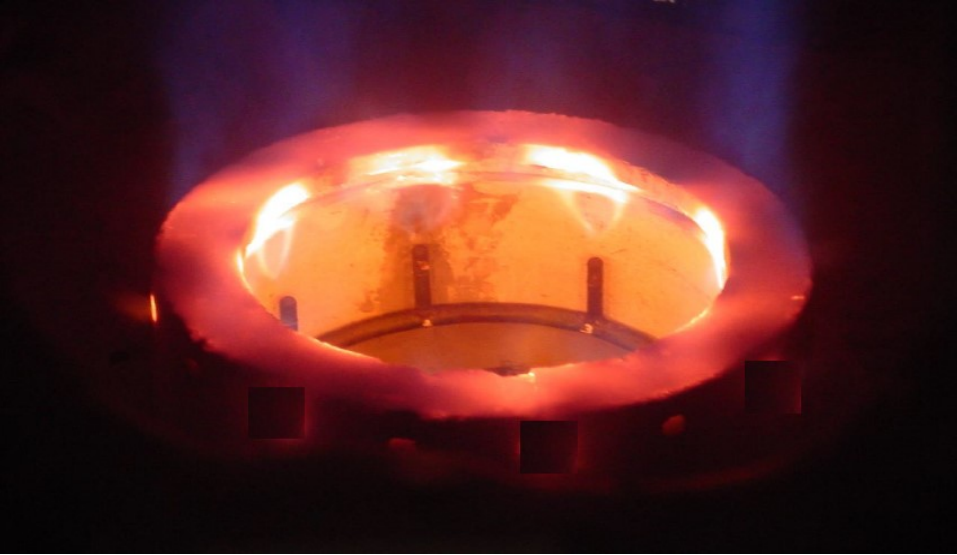

Burner maintenance and spare parts replacement

The engineer inspected each part of each burner in each furnace one by one and recorded the damaged components.

![]()

简体中文

简体中文