Elevated flare system

Upper steam overhead flare system - smokeless combustion

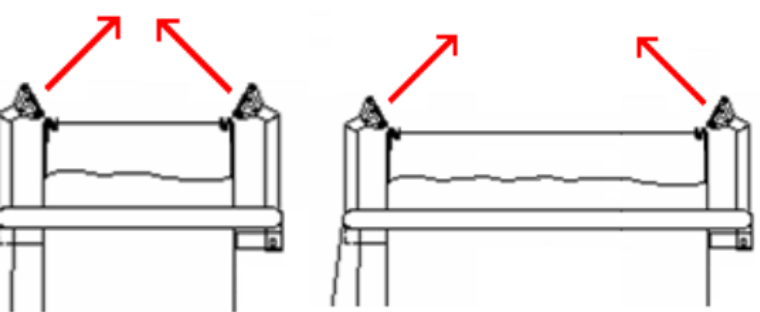

The Upper Steam (US) flare system is equipped with a high-efficiency, low-noise steam injection system to achieve smokeless combustion. The upper steam distribution pipe is installed at the top of the flare head, which can deliver steam into a series of stainless steel nozzles and inject it into the flare exhaust gas. The high-speed injection of steam can generate turbulence at the outlet of the flare head, inducing surrounding air into the exhaust gas. By inducing air into the exhaust gas, more oxygen is available for combustion, ensuring smokeless combustion of the exhaust gas and optimizing smokeless performance.

Advantages of the upper steam flare:

• Use the energy from steam injection to generate turbulence in the burner and draw air into the combustion zone, reducing or eliminating black smoke and achieving smokeless combustion

• The steam injection nozzle is made of castings, featuring an advanced nozzle design that maximizes air intake while minimizing noise. The low-noise design ensures a longer lifespan with minimal maintenance, thereby reducing costs

• Easy to install and operate

Removable elevated flare system

The detachable elevated flare system utilizes a specially designed custom tower structure. This tower system incorporates an internal flare stack lifting system, which utilizes ground-based lifting winches, turning winch systems, pulley blocks, and lifting beams on the tower to install or dismantle each flare stack in sections and lift them into place without the need for large cranes.

The detachable flare system typically features multiple flare tubes sharing the same tower. Since it allows maintenance personnel to detach the flare tubes into sections to the ground without climbing to the top of the tower, it enables the lifting and ground maintenance of a single flare tube while other flare tubes on the same tower maintain normal operation. All operations are conducted on a safe bottom platform equipped with a radiation protection cover, ensuring the safety of personnel.

The development of detachable flares has addressed the challenge of ensuring safe and smooth flare maintenance operations in multi-unit plants where maintenance of different units is not synchronized. These flares are commonly used in large-scale integrated refining and petrochemical projects, as well as oil storage and transportation tank areas.

Advantages of the detachable elevated flare system:

• The flare stack can be lifted and lowered into position without the need for a large crane, significantly reducing maintenance costs and extending the operational cycle

• Under other operating conditions where the flare stack remains operational, any flare stack can be lowered to the ground for maintenance, minimizing the downtime of the flare system

• A spare flare can be added to cope with any potential releases that may occur during flare maintenance

• Supporting multiple flare stacks with the same tower can significantly reduce the total area required

• It can reserve a flare position for future planning of the device, saving land use

• Meet environmental protection requirements, maximize design monitoring based on actual emission data, and implement emission control measures for different emission situations. Reduce VOCs emissions while increasing enterprise efficiency

![]()

![]()

Strong computing power and fluid dynamics simulation capability

• Physical properties and combustion calculation of flare gas

• Torch thermal radiation calculation

• Calculation of separating tank - water seal tank

• Pressure drop calculation of the flare system

• Torch noise calculation

简体中文

简体中文