Sulfur recovery burner

Technical advantages of high-strength burner

The main burner, online furnace burner, and reduction furnace burner designed for the sulfur recovery unit

Both the burner and the tail gas incinerator burner are high-power burners.

The design of high-strength burners ensures optimal mixing of air (or pure oxygen) and fuel, resulting in a smaller flame volume for the same amount of fuel.

Flame combustion intensity parameter = heat generated per unit volume of flame, unit (MMBTU/hr)/ft3 or MW/m3

Technical advantages of high-strength burner

Comparison of relative flame combustion intensity parameters among different burners (using natural gas as fuel)

– Natural draft burner = 130,000 BTU/hr/ft3

– Forced air burner = 150,000 - 250,000 BTU/hr/ft3

– Boiler burner = 150,000 - 350,000 BTU/hr/ft3

– High-intensity burner = 900,000 - 1,100,000 BTU/hr/ft3

(9-11 MW/m3)

Specific design structure of high-power burner: taking the main burner as an example

A combustion chamber with a refractory lining and a jacket design, where fuel gas/acid gas and air (pure oxygen) are mixed and burned under high temperature conditions.

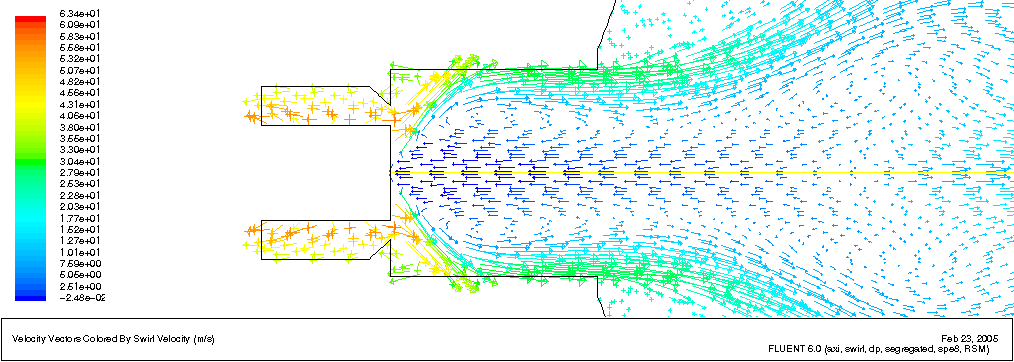

Air enters the windbox through the jacket on the outer wall of the combustion chamber. Inside the windbox, there is a set of gas deflectors composed of blades, which serve to accelerate the rotation of the air. The rotating air enters the combustion chamber through the throat and can protect the lining surface inside the combustion chamber from flame impact.

(If it is a pure oxygen burner, the acidic gas passes through this guide plate)

The acid gas spray gun and the fuel gas spray gun are designed concentrically (tube within tube). The acid gas spray gun is equipped with vortex blades to enhance the rotational intensity of the acid gas. This concentric spray gun ejects acid gas/fuel gas into the rotating air through a throat with high intensity and high turbulence.

The high-intensity burner of the sulfur production reactor forms a rotating flow field in the combustion chamber through the high-speed rotating acidic gas fluid. A low-pressure zone is formed at the center of this high-speed rotating flow field, which can cause the backflow of combustibles in the combustion chamber.

The re-circulated combustibles, along with the injected oxygen-enriched air and fuel, interact and mix thoroughly within the combustion chamber. This thorough mixing enables the combustibles to burn in a near-ideal state, thereby significantly elevating the flame temperature.

简体中文

简体中文